History

Our long family history, expertise and customer service sets us aside from any other company in the industry. We are proud to be born and bred in the Black Country where our business has never left the family. Currently being managed by our two fifth generation Directors, Ivan and Robin, with their children Nathan, Rebecca and Amelia, our sixth generation, eagerly learning the ropes in this ever-changing industry, bringing with them new ideas for more modern outlooks and environmental improvements that we can implement moving forward.

1800's

The company was started in 1864 by Stephen Grainger, blacksmiths in a small smithy at the bottom of the garden in Northfield Road, Netherton, and Stephen Grainger was born in September 1841.

In 1856 he was employed at Lloyd & Lloyd's Bilston Ironworks to hand forge fittings from wrought iron before setting up his own business in 1864. Isaac, his son, was born in 1866 and was later to give his name to the company. William Arthur was born in 1890 and followed on into the business with his sister, Frances May.

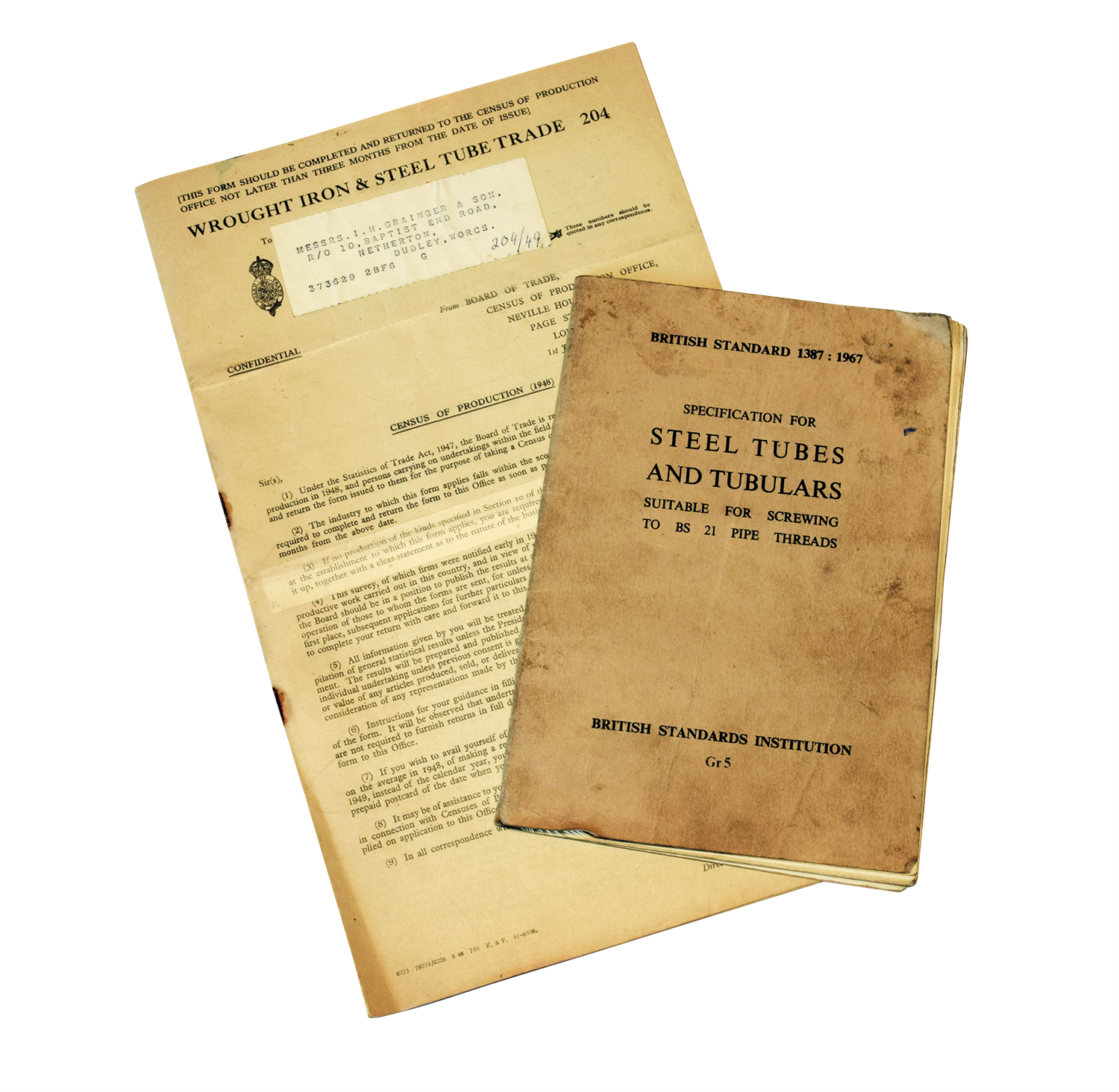

The Grainger’s then diversified into hand forged fittings for water and steam industry. During this early period the principal activity was the hand forging of tube fittings for gas, water and steam with eight blacksmiths fires; the blast for which was provided by a 10hp gas engine driven fan.

In 1905 the first tapping machine was installed. It was a Samuel Platt tapping machine. This machine was donated to the Black Country Museum when it opened in 1978.

1920's

Through both World Wars, Arthur Grainger continued to produce and run the factory which was now based in Baptist’s end. Business boomed. After the bombings all over the country people needed to build new homes and business. Meaning everyone needed a new water and gas fittings in their homes.

The 1920's depression saw the introduction of finishing and screwing machines for facing & tapping the forgings and cutting & threading tube. Overhead shafting was installed to drive the facing and tapping machines from the gas engine. This was later replaced by an electric motor. A separate installation with its own electric motor provided power to drive a 3” Tangential screwing machine of Czechoslovakian origin, a Taylor Tube Cutting machine and a guillotine for cutting the strip for the forging of the fittings. This broadened the customer base to engineers and plumbers’ merchants.

1930's

Isaac died in 1931 when ownership of the company passed to his widow, Mary, and was run by Arthur and May. More tube screwing and bending machinery was introduced towards the end of the Second World War. Due to the lack of hand forging skills and the demise of the supply of British-made wrought iron, the forged fitting side of the business gradually reduced and was finally discontinued shortly after the war.

1950’s

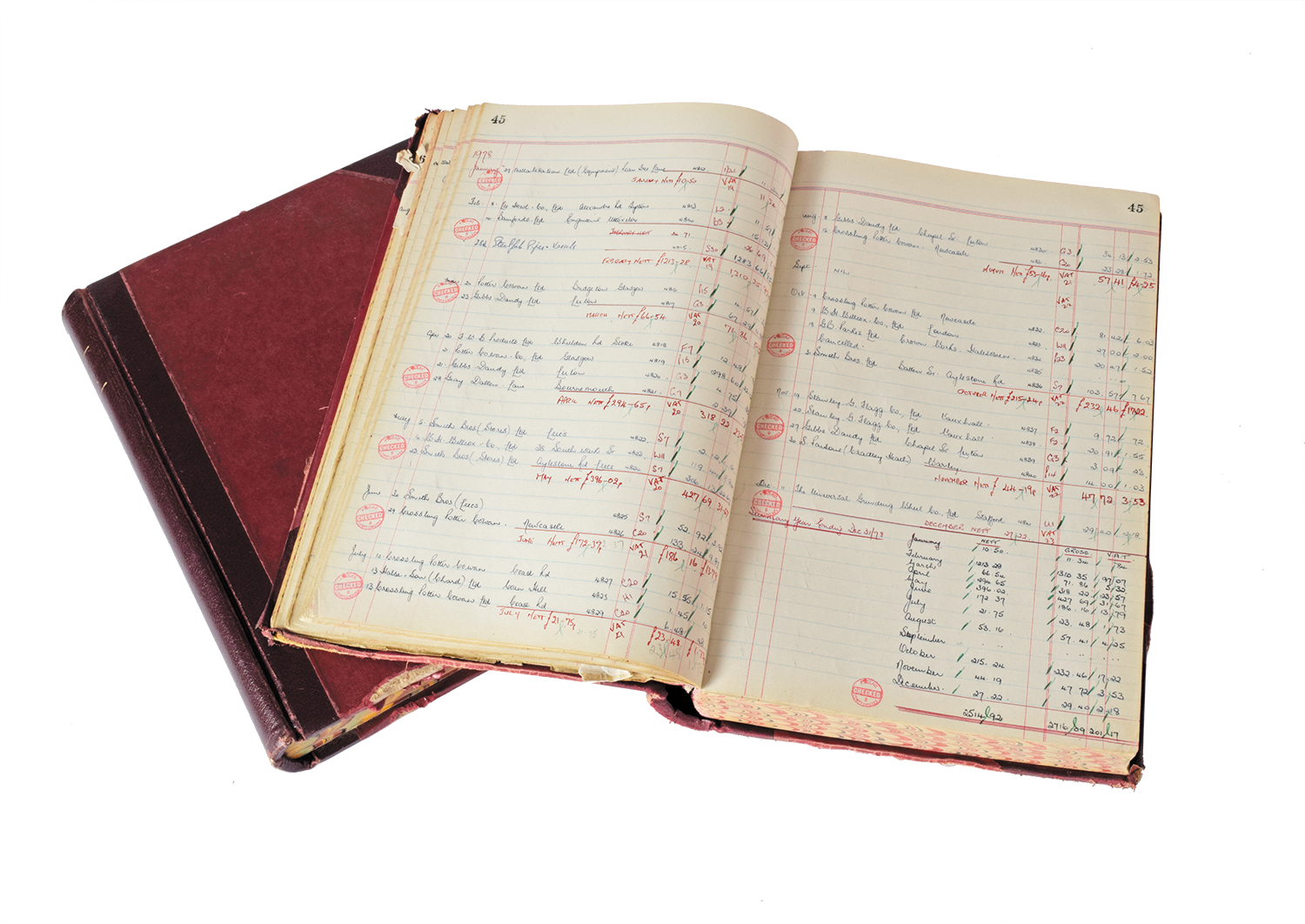

In 1952 Mary handed over the business to Arthur and May when the title became Isaac H. Grainger & Son.

1956 marked Isaac H Grainger and Sons Ltd as an official registered business with companies’ house. The firm was made into a Limited Company in 1956, shortly after David & Neville joined.

40 threading machines and 7 open hearth furnaces were brought into the factory. These then made full fittings not just the components.

1970’s

The manufacturing branch was moved to Pembroke Dock, South Wales and the Bapsist end site in Dudley became a stockiest for the midlands. There, David set up a new company, Grainger Tubolt, to take advantage of the local demand for tube, tube fittings, bolts, flanges and general engineering requirements.

1980’s

In the early 1980’s it became no longer viable as a manufacturing unit and production was returned to Netherton. David left the company to continue to develop the Grainger Tubolt operation, which is still thriving today, while Neville restructured and developed Isaac H. Grainger & Son Ltd., specialising in tubular all-thread and products made from it.

Neville’s sons, Ivan, and Robin joined the company after leaving school in 1979 and 1982 respectively. This introduced the company to the component supply and eventual manufacture of pedestals for the computer floor industry.

Access Flooring developed in the heart of the midlands. Some say the original idea came from various companies in Telford.

We started to supply threaded tube and threaded sockets to manufacturers in Access flooring.

1990’s

Since the 90’s the building regulations within the UK have really promoted access floors due to their efficiencies. We began to manufacture and assemble full pedestals in house.

Our specialized thread rolling machinery was developed in house and is still used today.

2000’s

With a healthy growth during the 1990’s production at Baptist End Works developed substantially and the opportunity arose to enable the Company to move to bigger and better premises. After 100 years at Baptist End, the move was made during the year 2000 to the newly named site, “Century Works”, in Gawne Lane, just 1 mile away from Baptist End and only ½ mile from the original site in Northfield Road.

Machinery innovations led to us donating our old lathe machinery from our original factory to the Black Country Museum.

Various growth and improvements carried out on the site to create a better working environment for all.

With an increasing demand for Raised Access Flooring Grainger’s went from strength to strength.

2010’s

In 2014 we celebrated our 150th birthday with an outstanding meal, endless glasses of fizzy bubbles, and casino evening. Suppliers and customers came from far and wide to celebrate with us. There was a great atmosphere, plenty of ruminations and plenty of chips rolling on the tables all in the name of charity.

ISO Environmental and ISO Quality was achieved. Recognizing the outstanding efforts of our company and leading the way in Access Flooring.

Nathan, Amelia, and Rebecca joined the family business as 6th generation of Grainger’s.

Neville Hamilton Grainger sadly passed away in July 2019. We celebrated his life.

2020’s

Today, we supply a comprehensive choice of products from all-thread, pipe fittings and tubes to a complete range of raised access flooring systems including a variety of access flooring accessories.

An access floor has almost become a necessity in offices and commercial spaces owing to their unmatched convenience and benefits.

Global distribution of Raised Access Flooring.

Priding ourselves on being the only UK Manufacturer of raised access flooring pedestals.

The industry’s most trusted name in Access Flooring.

Regularly donating to various important and close to our heart charity events.

Now diversifying into various other sectors with our outstanding customer service and quality leading the way.